What is Hazardous Area?

A Location where fire / explosion hazards may exist due to presence of flammable gases, vapors, liquids, combustible dust or ignitable fibers

What is Area Classification?

Area classification is a method of analyzing & classifying the environment where explosive gas atmosphere may occur

Combustion = Flammable Substance + Oxygen + Ignition

Why is it done?

To identify areas which may be potential sources of hazard for fire/explosion. Purpose of such identification is selection of electrical equipment.

Why Area Classification?

Hazardous Area Classification is a method of analyzing and classifying the environment where explosive gas atmospheres may occur to allow the proper selection of electrical apparatus to be installed in that environment.

Ignition sources are not considered for ESD, Sparks, Lightning, Flames, Fires, Hot surfaces

Hazardous Areas are classified in zones based on the frequency of the appearance and the duration of an explosive gas atmosphere.

Most common codes and standard used:

IEC-79-10 – Electrical apparatus for explosive gas atmosphere-Part 10: Classification of hazardous area.

API RP 500 – Recommended practice for classification of locations for electrical installations at Petroleum facilities classified as Class 1, Division 1, Division 1.

API RP 505 – Recommended practice for classification of locations for electrical installations at Petroleum facilities classified as Class 1, Zone 0, Zone 1, and Zone 2.

Indian petroleum Rules.

OISD-STD-113 – Classification of areas for Electrical installations at Hydrocarbon processing and handling facilities.

IS: 5572 – Classification of Hazardous Areas (other than mines) having Flammable Gases & vapours for Electrical Installations.

Hazardous Area Classification is not applicable for following:

Mining applications, Explosive manufacturing, Catastrophic failures, Ignition sources other than electrical apparatus

INPUTS FOR HAZARDOUS AREA CLASSIFICATION

Hazardous area classification is done based on the inputs obtained from process department related to properties of hazardous substances and put in a specific format which is called “HAZARDOUS AREA SOURCE LIST”. This contains followings:

- Equipment Tag No.

- Equipment name

- Hazardous area substance

- Grade of release

- Lower Flammability Limit

- Flash point of liquids

- Process Temperature

- Flammable or not

- Gas/ Vapor Density

- Auto ignition Temperature

- Temperature Class

- Gas Group

- Extent of Classification

Hazardous area Substance data present in the equipment

- Phase (Gas/Vapour/Liquid)

- Substance (Naptha, Methane, Hydrogen etc)

- Concentration in % volume of individual components

Type of Release/Grade of Release

- Continuous (>=1000 hrs/year)

- Primary (>10 hrs/year but <1000 hrs/year)

- Secondary (<10 hrs/year)

Process Temperature

Temperature at which a particular liquid or gas is handled, processed or stored.

Lower Flammability Limit

The lower % by volume of concentration of gas in a gas air mixture that will form an ignitable mixture.

Gas/Vapour Density

- Density of gas/vapour relative to air.

- API/IEC –relative density <0.8 – lighter than air relative density >1.2 – heavier than air Gas/Vapour Density.

Flash Point

The minimum temperature at which the liquid gives so much vapour that this vapour when mixed with air, forms an ignitable mixture and gives a momentary flash on application of a small pilot flame under specified condition.

Auto Ignition Temperature

The lowest temperature of a heated surface at which under specified conditions, the ignition of a flammable substance in the form of a gas or vapour mixture with air will occur.

HAZARDOUS AREA CLASSIFICATION- CLASSES, ZONES/DIVISIONS

Hazardous area shall be classified into Classes and Zones or Divisions as follows-

- Class I Location – Flammable gases, vapors or liquids are present

- Class II Location – Combustible dusts are present

- Class III Location – Ignitable fibers and combustible flying are present

Zone – 0

An area in which explosive gas atmosphere is present continuously or it present for long period of time. As per API-505 rate of release for such an area shall be 1000Hrs/year or more.

Example:

- Vapour space above closed process vessels

- Storage tank or closed containers

- Areas containing open tanks of volatile,flammable liquids etc.

Zone – 1

Flammable gas or vapour concentration is likely to exist in the air under normal operating conditions. Flammable atmospheric concentration is likely to occur frequently because of maintenance, repairs or leakage. Failure of process, storage or other equipment is likely to cause an electrical system failure simultaneously with the release of flammable gas or liquid. Flammable liquid or vapour piping system containing valves, meters, screwed or flanged fittings in an inadequately ventilated area.

Example:

- Imperfactly fitted peripheral seals of floating roof tanks

- Inadequately ventilated pump rooms for volatile, flammable liquids

- API seperator

- Oily wastewater sewer/basins

Zone – 2

Areas in which an explosive gas / air mixture is not likely to occur in normal operation, and if it occurs, it will exist only for a short time. As per API-505 rate of release for such an area shall be less than 10 Hrs/year

Example:

- The system handling flammable liquid or vapour is in an adequately ventilated area and is so designed and operated that the explosive or ignitable liquids, vapours or gases will normally be confined within closed containers or closed systems from which they can escape only during abnormal conditions such as accidental failure of a gasket or packing.

- As per API 500 gas groups are categorized into Group A, Group B, Group C, Group D

- As per IS / OISD-STD-113 / IEC / API-505 Electrical Apparatus for explosive Gas atmosphere are categorized into Group-I and Group-II.

- Group I is applicable for coal mining industries hence shall not be considered here.

- Group II consists of following sub-groups according to the nature of the explosive gas atmospheres for which it is intended.

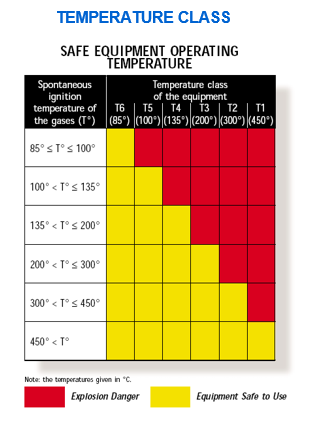

Temperature Classification

- Temperature classification is done for equipments with regard to the Maximum surface temperature of any part of the equipment under normal or fault conditions at an ambient temperature of 40°C.

- Temperature class ranges from T1 to T6. Maximum surface temperature (in deg centigrade) for different temperature class is given below: –

SELECTION OF ELECTRICAL EQUIPMENT IN HAZARDOUS AREAS

How to select equipment for various zones?

Selection Criteria

- Gas Grouping (based on ignition energy)

- Temperature Classification

- Classified Zones

RECOMMENDED PROTECTION METHODS FOR ZONE O

No electrical equipment should be allowed. When this is not practicable, Ex ‘ i ‘ (ia or ib) apparatus or circuits to be used.

No transformers, motors, lights, switch gear or control gear.

RECOMMENDED PROTECTION METHODS FOR ZONE 1

- Motors- Ex d, Ex p

- Transformers & Capacitors – Ex d

- Control & Instrument Transformers – Ex i

- Lighting Fitting – Ex d

- Switch Gear & Control Gear – Ex d

- Communication/ Telephone equipment/Meters – Ex i

- Portable Hand Lamps- Ex i

RECOMMENDED PROTECTION METHODS FOR ZONE 2

Protection Methods for Zone 2:

- Intrinsically Safe (Ex i): This method limits electrical energy to prevent ignition of explosive atmospheres.

- Increased Safety (Ex e): This method enhances the safety of normally non-sparking components.

- Flameproof Enclosure (Ex d): This method uses enclosures that can withstand internal explosions and prevent the spread of flames.

- Restricted Breathing (Ex nR): This method limits the ingress of flammable substances into the enclosure.

- Encapsulation (Ex m): This method encloses electrical components in a solid material to prevent ignition.

- Pressurization (Ex p): This method uses pressurized air to prevent the entry of flammable substances.

- Non-Sparking/Arcing Parts (Ex nC): This method uses components that do not produce sparks or arcs.

- Sealed or Encapsulated Device: This method protects against the ingress of flammable substances through sealed or encapsulated components.

- Hermetically Sealed: This method uses a seal to prevent the ingress of flammable substances.

Useful Article

Good Article