Introduction

Industrial automation systems are the backbone of modern manufacturing, processing plants, utilities, and infrastructure. When engineers and plant managers plan automation projects they often weigh three core control paradigms: Programmable Logic Controllers (PLC), Distributed Control Systems (DCS), and Supervisory Control and Data Acquisition (SCADA). Each approach has specific strengths, typical applications, and architectural trade-offs. Choosing the right one depends on process complexity, safety requirements, availability goals, scalability, and budget.

This article explains how PLC, DCS, and SCADA work, compares them across technical criteria, and provides a decision framework to help you choose the best option for a given industrial automation scenario.

Quick definitions

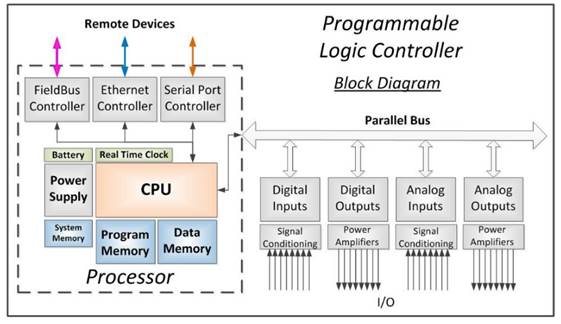

- PLC (Programmable Logic Controller): A ruggedized industrial computer that executes deterministic control logic (ladder, structured text, function block) for discrete and continuous processes. PLCs are typically used for machine-level and sequence control.

- DCS (Distributed Control System): An integrated control platform designed for complex, continuous-process operations (chemical, oil & gas, power generation). A DCS distributes control loops across multiple controllers and provides high-level operator stations, advanced process control (APC), and tight integration with plant historians.

- SCADA (Supervisory Control and Data Acquisition): A software-centered architecture focused on remote monitoring, data acquisition, and supervisory control. SCADA systems collect telemetry from remote terminal units (RTUs) or PLCs and present alarms, trends, and control capabilities to operators — commonly used in utilities, oil & gas pipeline networks, water distribution, and large geographically dispersed systems.

Core components & architecture (high level)

PLC architecture

- Field I/O modules: Digital/analog input and output modules connected to sensors and actuators.

- CPU/Controller: Executes control program, performs fast loop control and sequencing.

- Communication buses: Ethernet/IP, Modbus TCP, Profinet, EtherCAT, etc.

- HMI (optional): Local operator panels or centralized HMIs for machine operators.

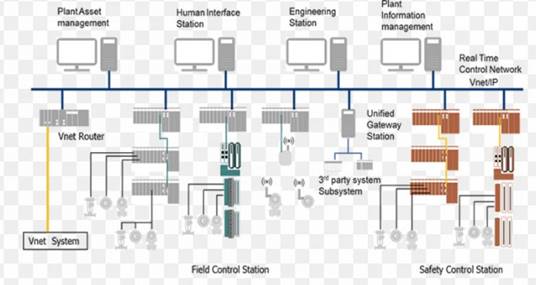

DCS architecture

- Controller islands: Redundant controllers distributed across the plant, often organized by process area.

- Operator stations: Centralized control room with multiple operator workstations and advanced process displays.

- Engineering station: For control strategy development, configuration and simulation.

- Historian & APC: High-capacity data archival and model‑based control loops.

- Fieldbus integration: FOUNDATION Fieldbus, HART, Profibus PA, Ethernet‑based fieldbus.

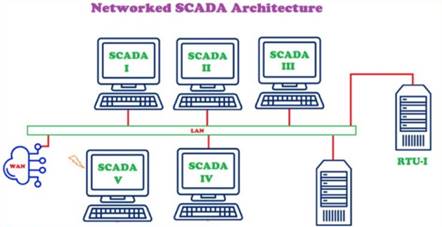

SCADA architecture

- Remote telemetry units (RTU) / PLCs: Collect and pre-process field data at remote locations.

- SCADA server: Central server(s) running SCADA software (data acquisition, alarm management, historian).

- HMI / Web clients: Dashboards, operator consoles, mobile clients for remote monitoring.

- Communication links: Wide area networks, cellular, satellite, radio modem, secure VPNs.

📘 BOOK EMERGING ELECTRICAL ENGINEERING TECHNOLOGIES — Buy on Amazon

When to choose a PLC

PLCs shine when you need fast, deterministic control for discrete machines or modular processes.

Typical scenarios:

- Packaging lines, conveyor sequencing, robotic cells

- Individual motor starters, pump sequencing, simple batching systems

- Machine retrofit projects where footprint, cost and ease of maintenance matter

Advantages:

- Cost-effective for machine-level control

- Fast I/O response and deterministic scan times

- Wide vendor ecosystem and modular I/O choices

- Easy to program using ladder logic and IEC 61131 standards

Limitations:

- Less feature-rich for advanced process control or integrated historian needs

- Can become complex when used to manage hundreds of control loops across a plant

When to choose a DCS

DCS is purpose-built for continuous, large-scale, and safety-critical processes that require integrated control, redundancy, and sophisticated operator support.

Typical scenarios:

- Refinery units, petrochemical plants, pulp and paper, power plants

- Processes that require tight loop performance, regulatory control, and advanced regulatory interlocks

Advantages:

- Engineered for process stability and high availability (redundant controllers, I/O, and networks)

- Integrated tools for control loop tuning, APC, and batch management

- Mature alarm management and operator training simulators

Limitations:

- Higher upfront cost (hardware and licensing)

- Vendor lock-in risk; configuration often proprietary

- Longer engineering cycle and higher project complexity

When to choose SCADA

SCADA is the go-to for distributed, geographically spread assets requiring centralized monitoring and remote control.

Typical scenarios:

- Water/wastewater networks, electrical distribution, oil & gas pipelines, metro systems

- Any infrastructure where remote telemetry over WAN/cellular is needed

Advantages:

- Excellent for wide-area supervisory monitoring and control

- Flexible client-server architecture; supports many field device types

- Superior visualization for geographically distributed assets (maps, GIS integration)

Limitations:

- SCADA is supervisory — it is not optimized for high-speed deterministic control loops

- Security considerations (exposed communication links, remote access vulnerabilities)

Feature-by-feature comparison

| Feature | PLC | DCS | SCADA |

| Primary use | Machine & sequence control | Continuous process & large plant control | Remote monitoring & supervisory control |

| Typical latency | Very low (ms) | Low (ms to sub-second) | Higher (seconds, network-dependent) |

| Redundancy | Possible but often limited | Native, high-availability options | Server redundancy available, RTU redundancy less common |

| Scaling | Modular, but can be complex at plant scale | Designed to scale across complex plants | Designed to scale across geography |

| Engineering effort | Low–medium | High | Medium (SCADA HMI + RTU/PLC config) |

| Cost | Low–Medium | High | Medium |

| Best for | Machines, modular systems | Refining, continuous chemical processes | Utilities, pipelines, distributed assets |

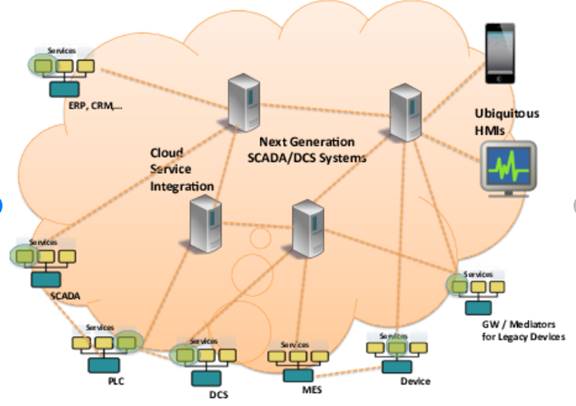

Integration patterns — combining PLC + DCS + SCADA

Real-world plants rarely use only one paradigm. Typical patterns:

- PLC at machine level + DCS at plant level: PLCs handle fast machine I/O and sequencing. The DCS integrates higher-level process control and historian functions.

- PLCs with SCADA supervisory layer: PLCs/RTUs handle local control; SCADA provides centralized monitoring, trending, alarm management and operator dashboards.

- Hybrid approach: A DCS controls core continuous process, while SCADA monitors geographically dispersed utilities and integrates via OPC/OPC UA or MQTT.

Key selection criteria — a checklist for engineers

Use this checklist when evaluating which system to deploy:

- Process type — Discrete machine, batch, or continuous process?

- Geographic spread — Is control confined to a single plant or spread across many remote sites?

- Required response time — Do you need millisecond-level determinism? If yes, favor PLCs.

- Availability & redundancy needs — Mission-critical process with required 24/7 uptime favors DCS.

- Integration & scalability — Will the system need to scale to hundreds of loops or thousands of I/Os?

- Safety & regulatory requirements — Are safety instrumented systems (SIS) or certified controllers required?

- Vendor dependency — Are you comfortable with proprietary ecosystems or prefer open/standards-based stacks?

- Engineering resources & skillset — Do you have PLC programmers, process control engineers, SCADA integrators?

- Budget & total cost of ownership (TCO) — Include engineering, license, maintenance, and lifecycle costs.

- Cybersecurity posture — Especially for SCADA, ensure secure VPNs, firewalls, and IEC/ISA security best practices.

Implementation considerations & best practices

- Define control boundaries clearly: Decide which loops need to be inside the DCS (tight regulatory loops) vs. handled by PLCs.

- Standardize communication: Use OPC UA, MQTT, or standard industrial protocols to reduce integration pain.

- Design for redundancy where needed: Critical control loops should have redundant controllers, I/O and communication paths.

- Alarm management: Implement ISA‑18.2 / IEC alarm management lifecycle to reduce nuisance alarms and prioritize operator response.

- Version control & testing: Use source control for logic (Structured Text, function blocks); conduct FAT/SAT and simulated commissioning.

- Cybersecurity: Follow IEC 62443 framework; segment control networks, employ DMZ for IT/OT crossing, use certificates for authentication.

- Human factors: Design HMIs for situational awareness — show process states, clear alarm prioritization, and allow for efficient operator actions.

Short case studies

Case study 1 — Packaging plant (PLCs + SCADA)

A consumer goods packaging line used PLCs for fast machine control (pick‑and‑place, indexing, labelers). A centralized SCADA system aggregated data from multiple lines for OEE tracking and alarm roll‑up. This combination kept machine response times low while enabling plant‑level analytics.

Case study 2 — Refinery unit (DCS with PLC islands)

A crude distillation unit used a DCS for primary process control, with PLC islands for motor control and non‑critical I/O. The DCS provided APC, advanced alarm management and redundancy. Integration was via fieldbus and OPC links.

Case study 3 — Water distribution network (SCADA)

A municipal water utility deployed SCADA across hundreds of pumping stations using RTUs and cellular telemetry. Operators used GIS overlays, trend analysis, and remote valve control to manage distribution efficiently.

Cost & lifecycle considerations

- Upfront costs: DCS > SCADA > PLC (generally). Licensing, engineering tools, and redundancy increase DCS cost substantially.

- Maintenance & support: DCS vendors often offer lifecycle support and upgrades, whereas PLC + SCADA mixes may require multiple third‑party integrators.

- Obsolescence risk: Consider vendor roadmaps — migrating proprietary systems is costly. Favor open standards where long‑term flexibility is needed.

Final decision matrix — practical guide

- Choose PLC when: The project is machine‑centric, requires low latency, and budget and time are constrained.

- Choose DCS when: You manage a continuous, safety‑critical process requiring integrated control, redundancy, and advanced process tools.

- Choose SCADA when: You need centralized monitoring and supervisory control across geographically spread assets.

- Choose hybrid: Most real plants use a hybrid mixture — use the matrix above to decide control partitioning.

Conclusion

There is no single “best” automation system — each paradigm (PLC, DCS, SCADA) has a defined role and excels in particular contexts. The smart approach is to evaluate process needs, response time, availability, and lifecycle costs, then map those requirements to the strengths of each system. In many cases, a hybrid architecture that combines PLC determinism, DCS process management, and SCADA supervisory oversight yields the best balance of performance, cost and maintainability.

“Hello, Monetag!”