Electric motors are the lifeline of modern industrial plants — from manufacturing floors and oil refineries to HVAC systems and water treatment facilities. Unexpected motor failure can halt production, cause downtime losses, and lead to safety hazards.

According to IEC 60034-1 (2025 revision) and IEC 60034-11 (Thermal Protection), the reliability of motors heavily depends on periodic preventive maintenance (PM) rather than reactive repair.

Preventive maintenance ensures that mechanical wear, insulation degradation, and operational anomalies are detected early — before catastrophic breakdowns occur. This guide provides a comprehensive 2000-word technical overview and checklist for preventive maintenance of motors as per IEC Standards 2025.

Objective of Preventive Maintenance

The main objective of preventive maintenance is to increase reliability, extend service life, and ensure safety of electric motors.

It helps industries achieve:

- Reduced unplanned outages

- Compliance with IEC and ISO reliability targets

- Optimized Mean Time Between Failures (MTBF) and Mean Time to Repair (MTTR)

- Improved energy efficiency

In essence, preventive maintenance transforms plant reliability from “reactive repair” to “predictive intelligence.”

📘 Buy “MOTOR ENCLOSURES AND COOLINGS” on AmazonReference IEC Standards

The 2025 IEC motor standards specify requirements for performance, safety, and testing. The following are most relevant for maintenance engineers:

| IEC Standard | Title | Description |

| IEC 60034-1 | Rotating electrical machines – Rating and performance | Defines performance limits, voltage tolerance, and temperature rise |

| IEC 60034-11 | Thermal protection | Specifies methods for preventing overheating |

| IEC 60034-12 | Starting performance | Details torque-speed characteristics |

| IEC 60034-14 | Mechanical vibration | Sets permissible vibration levels |

| IEC 60204-1 | Safety of electrical equipment for machinery | Covers protective earthing and safety isolation |

| IEC 60364-6 | Verification and testing | Defines electrical inspection and test intervals |

Each of these standards is vital for ensuring motors meet international reliability and safety norms.

📘 Buy “STARTING METHODS OF MOTORS” — eBookTypes of Maintenance for Motors

IEC classifies maintenance into four categories:

- Preventive Maintenance (PM):

Time-based maintenance carried out at fixed intervals.

Example: Bearing lubrication every 3,000 operating hours. - Predictive Maintenance (PdM):

Condition-based monitoring using sensors and analytics (temperature, vibration, current). - Corrective Maintenance (CM):

Action taken after fault or degradation is detected (repair or replacement). - Overhaul Maintenance (OM):

Comprehensive disassembly and refurbishment of the motor after extended service (typically 5–8 years).

Among these, preventive and predictive are considered best practice under IEC 60034-25:2025.

ONLINE CONDITION MONITORING SYSTEM (OLCMS) Buy on Amazon »Preventive Maintenance Checklist (IEC 2025)

Preventive maintenance tasks are divided into five major categories.

1. Visual Inspection

- Inspect nameplate and terminal box for corrosion or damage.

- Check cable glands and sealing gaskets for deterioration.

- Verify mounting bolts and foundation integrity.

- Look for oil leaks, rust, or contamination on motor body.

- Confirm that ventilation openings are clean.

2. Mechanical Inspection

- Check shaft alignment using dial indicator or laser alignment tool.

- Inspect bearing housing for temperature rise and vibration.

- Listen for abnormal bearing noise.

- Verify coupling condition and tightness.

- Check fan blades and cooling fins for obstruction.

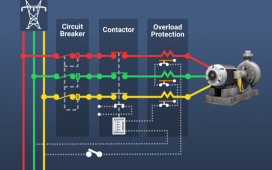

3. Electrical Inspection

- Measure Insulation Resistance (IR) using a megger (as per IEC 60034-1).

- Record Polarization Index (PI) value (should exceed 2.0 for healthy insulation).

- Measure winding resistance across all three phases.

- Verify phase balance and earth continuity.

- Check tightness of terminal lugs and connections.

4. Operational Tests

- Record supply voltage and load current of each phase.

- Monitor power factor and load variations.

- Observe startup torque and acceleration time.

- Measure vibration amplitude (should not exceed 4.5 mm/s RMS for small motors).

- Conduct temperature scan with infrared camera.

5. Lubrication and Cleaning

- Use manufacturer-recommended grease (typically lithium-based).

- Avoid over-lubrication.

- Clean stator housing, cooling ducts, and terminal box.

- Ensure filters and vents are free of dust and oil deposits.

Maintenance Frequency:

- Critical motors: Every 3 months

- Medium duty: Every 6 months

- Light duty: Annually

Thermal & Operational Checks:

Thermal management plays a crucial role in preventing insulation aging.

- Record winding temperature under full load.

- Compare readings with IEC 60034-1 limits (Class F = 155°C, Class H = 180°C).

- Perform IR thermography to identify hot spots.

- Inspect cooling fans and ducts for blockage.

- Calibrate overload relays and temperature sensors annually.

Overheating reduces insulation life exponentially — a 10°C rise above rated temperature can halve insulation life expectancy.

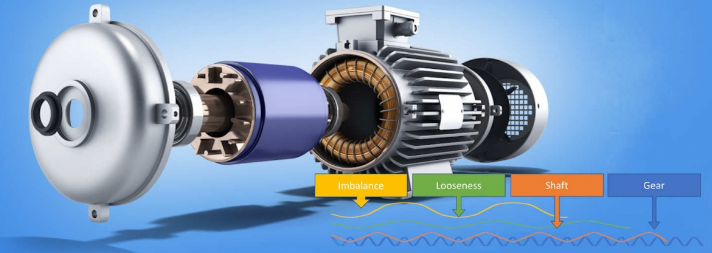

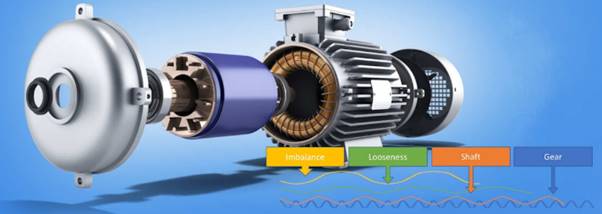

Predictive Maintenance (Condition Monitoring)

Predictive maintenance employs sensor data and AI-based analytics to detect early-stage faults.

Modern systems integrate with IEC 61850 and Modbus TCP communication protocols.

Key predictive tools include:

- Vibration Analysis: Detects imbalance, bearing wear, and misalignment.

- Motor Current Signature Analysis (MCSA): Identifies rotor bar and air gap defects.

- Partial Discharge Measurement: Monitors insulation deterioration in HV motors.

- Temperature Trend Analysis: Tracks heat accumulation patterns.

With predictive systems, maintenance becomes proactive, allowing early corrective actions before production loss occurs.

Documentation & Record Keeping

IEC 60364-6 mandates accurate record keeping for all electrical assets.

Each motor should have a maintenance logbook containing:

- Motor serial number, rating, and duty class

- Inspection and test dates

- Results of IR, PI, vibration, and thermal checks

- Maintenance personnel signature

- Observations and corrective actions

Proper documentation ensures traceability, audit compliance, and data-driven maintenance decisions.

MTBF, MTTR & Availability

Reliability metrics as per IEC 61709 and 60300-3 are key for evaluating motor performance.

- MTBF (Mean Time Between Failures)

MTBF=Total Operating HoursNumber of FailuresMTBF = \frac{\text{Total Operating Hours}}{\text{Number of Failures}}MTBF=Number of FailuresTotal Operating Hours - MTTR (Mean Time To Repair)

MTTR=Total DowntimeNumber of RepairsMTTR = \frac{\text{Total Downtime}}{\text{Number of Repairs}}MTTR=Number of RepairsTotal Downtime - Availability (%)

A=MTBFMTBF+MTTR×100A = \frac{MTBF}{MTBF + MTTR} \times 100A=MTBF+MTTRMTBF×100

A well-maintained motor can reach availability > 99.7% and an MTBF exceeding 50,000 hours.

Safety Precautions (IEC 60204-1)

Safety must be prioritized in every maintenance activity.

- Isolate the power supply and apply lockout-tagout (LOTO).

- Verify zero voltage using approved testers.

- Use PPE – insulated gloves, safety glasses, and antistatic shoes.

- Ensure all rotating parts have stopped before touching.

- Discharge stored energy from capacitors.

- Never perform insulation tests when the circuit is energized.

Digitalization & Future Trends (IEC 60034-25:2025)

The next generation of motor maintenance is digital and data-driven.

IEC 60034-25:2025 introduces guidelines for Smart Motor Management Systems (SMMS).

Emerging Technologies

- IoT-enabled sensors continuously monitor motor health.

- Edge computing devices analyze data locally for real-time response.

- AI algorithms predict bearing failure or winding short before occurrence.

- Cloud dashboards visualize key parameters for maintenance planning.

By 2030, most industrial motors will be equipped with IEC-compliant digital twins, enabling automatic optimization of performance, load, and energy usage.

EMERGING ELECTRICAL ENGINEERING TECHNOLOGIESIllustration

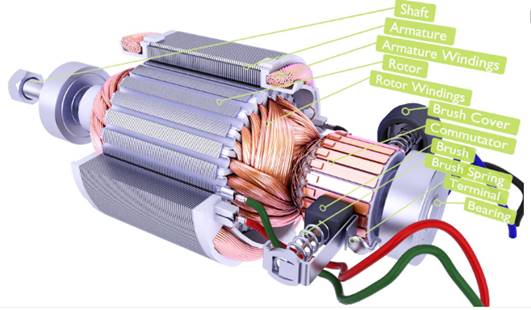

This diagram illustrates key internal components such as rotor, stator, windings, bearings, and cooling system — all critical inspection points during preventive maintenance.

Conclusion

Preventive maintenance of electric motors, when aligned with IEC 60034 (2025 Edition), ensures long-term reliability, reduced downtime, and energy savings.

By implementing structured PM programs, industries can:

- Extend motor life by up to 40%,

- Reduce unscheduled failures by 50–70%, and

- Maintain operational availability above 99.7%.

Integrating IoT, AI, and predictive analytics into maintenance systems will further enhance industrial reliability and sustainability in the coming decade.

🔧 Key Takeaways

- Follow IEC 60034 and IEC 60204 standards strictly.

- Perform regular IR, PI, vibration, and thermal tests.

- Maintain detailed documentation.

- Transition from reactive to predictive maintenance.

- Use digital tools for continuous health monitoring.