There is a wide range of starting methods. The selection criteria are mainly guided by short circuit capacity of the network, acceptable voltage drop (maximum starting current at minimum starting voltage), load torque, load inertia, starting time, starting duty category and temperature limitations of the machine due to its location in classified areas. The number of possible consecutive starts depends on the selected starting method.

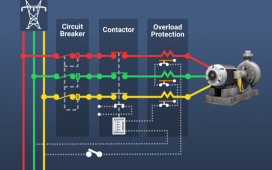

DOL Start

The DOL start is the most common, simple and economical starting method. It gives high starting torque but requires a stable supply. The biggest disadvantages are the high starting currents that cause voltage drop on weak networks & it imposes large mechanical and thermal stresses on the machine.

Reactor Start

By connecting a reactor in series with the motor during start, the starting current is decreased proportional to motor voltage. However, this also means a substantial (quadratic) reduction in the available starting torque. The advantage of this method is its low cost in comparison with other methods.

Auto-transformer Start

The effect of auto-transformer start is similar to that of reactor start. Using a transformer to limit the voltage reduces the starting current and the torque, but less so than the reactor start. The method is more expensive than reactor start. Autotransformer motor starters consist of a transformer with voltage taps that allow operating from reduced voltage to full voltage. The starting torque is reduced only in proportion to line current while in reactor starting the starting torque is decreased as the square of the line current. The taps can be changed during run up to give high synchronizing torque

Reactor/Capacitor Start

Reactor/capacitor start is used on networks with very low short circuit capacity. In this method a capacitor bank is energized during motor start in order to provide necessary reactive current to the motor.

During motor acceleration to rated speed, the capacitors are disconnected. If a large capacitor bank would remain permanently connected, the voltage could rise above motor’s maximum allowed level. For this reason the grid voltage or motor speed need to be monitored and controlled in such a way to connect/disconnect complete or part of the capacitors to avoid overcompensation and overvoltage. If the motor voltage reaches an intolerable level or if the motor has not accelerated to a suitable speed, the controller must open the mains. Synchronous machines can also be designed to provide reactive power neutralizing the advantages of this method.

Variable Frequency Drive Start

Although a static frequency converter is designed to continuous feed the machines, it can also be used exclusively for start-up2. The variable frequency drive (VFD) enables low starting currents because the motor can produce exactly the required torque at rated current from zero to full speed. The VFD soft-start provides smooth, step-less acceleration of motor and load while controlling inrush current and starting torque. As the voltage regulator soft-starters they can be used to control the stopping of the process. One VFD can be used to start multiple machines.

The synchronous machine (SM) with its main excitation and the running circuit breaker (RCB) are the components which are required to operate the load direct on line.

The task of the VFD is to accelerate the SM from zero up to nominal speed and synchronize it to the power supply system by closing the RCB, and optionally – after RCB has been opened – to decelerate the SM from nominal speed to standstill. Its main function is to control the energy exchange between the power system and the motor, which during acceleration and deceleration is operated at variable frequency and voltage.

.

Usefull article. keep it up!